Rail freight plays a crucial role in transporting goods over long distances, solidifying its position as a crucial part of the global transportation industry. With the market expected to grow from $247.4 billion in 2020 to $278.6 billion by 2026, rail freight is undergoing a significant transformation. While other modes of transport receive considerable attention, rail freight is harnessing innovative technologies to achieve unprecedented operational and maintenance efficiencies.

The Evolution of Rail Freight: From Tradition to Innovation

For decades, rail freight has been a reliable cornerstone of logistics, competing shoulder-to-shoulder with other transport giants such as the trucking industry. Railcars continue along their steel paths, carrying everything from coal to consumer goods, but beneath this seemingly unchanging exterior, a technological revolution is brewing. Telemetry devices are not just adding layers of data – they are fundamentally changing how rail operations are managed and optimized.

The adoption of IoT technology in rail freight has been met with cautious optimism. Railroads and freight operators, often entrenched in traditional methods, wonder if these new devices can deliver on their promises. To dispel doubts and demonstrate the potential of these innovations, detailed analysis and robust testing of telemetry systems like Trilogical’s RailBlazer are essential.

Why Telemetry Is a Game-Changer

Rail freight operations require a delicate balance of coordination. To succeed, operators must harmonize commercial, operational, and maintenance activities while ensuring shipper satisfaction. This intricate process hinges on the availability of precise, realtime data —an essential requirement that advanced telemetry systems like RailBlazer fulfill exceptionally well. These systems are not just about gathering data; they’re about transforming that data into actionable insights that enhance every aspect of railcar management.

Imagine having the ability to pinpoint the exact location of every railcar in your fleet at any moment, including shunting yards. Picture monitoring each railcar’s status in real time, ensuring optimal positioning, efficient loading and unloading, and quick responses to potential safety hazards. This is the transformative capability that RailBlazer IoT devices bring to the table.

RailBlazer offers precise tracking of railcar positions, ensuring every movement is accurately recorded and analyzed for maximum operational efficiency. Beyond positioning, accurate mileage tracking enables precise billing and better maintenance scheduling. Monitoring the loading and unloading processes saves valuable time and reduces “empty miles,” providing shippers with transparency they can rely on. The system’s capability to detect shocks and impacts is crucial, identifying safety risks and potential defects preemptively. Handbrake status alerts help prevent wheel damage caused by moving rail cars with the hand brakes applied, a problem estimated by the Association of American Railroads to cost $600 million annually.

Meanwhile, realtime trip and estimated arrival time monitoring ensures superior service quality, ensuring operations remain smooth and punctual.

RailBlazer’s Capabilities

Trilogical’s RailBlazer IoT device is designed to address the unique challenges of rail freight operations. It includes internal non-rechargeable batteries, a cellular modem, embedded sensors, and accurate GPS. The system captures, analyzes, and transmits required information based on predefined logic. External sensors connected via BLE implemented to provide reliable information under energy constraints, with a minimum operational period of 5 years.

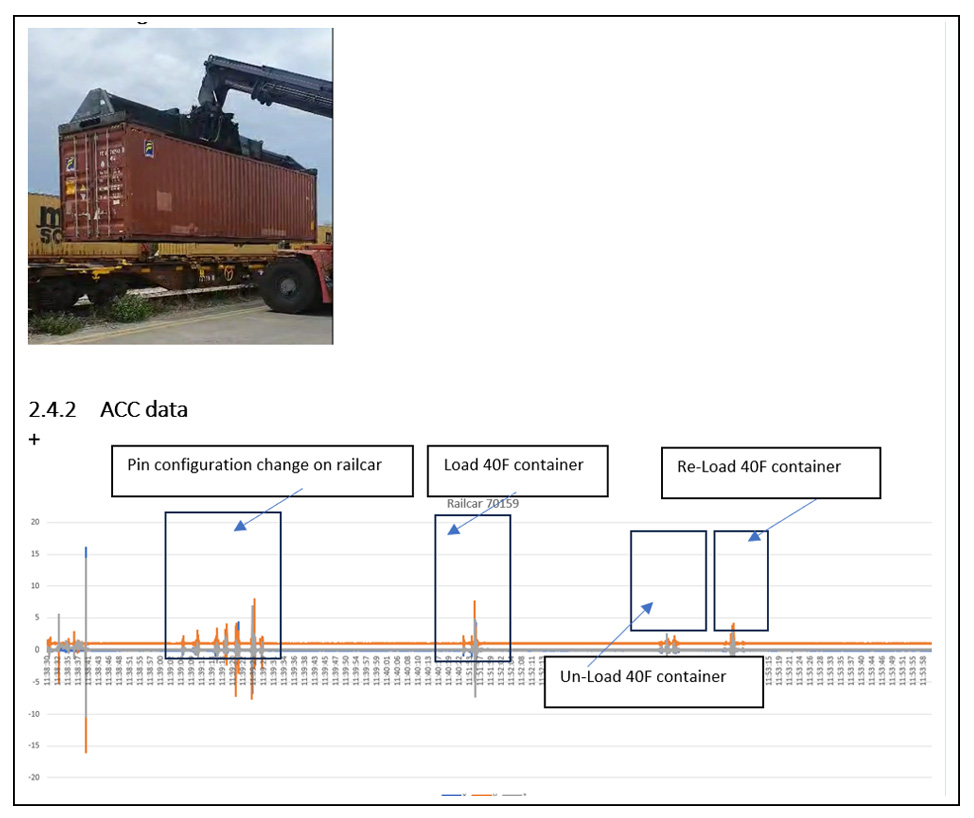

RailBlazer is designed to enhance rail operations and maintenance with advanced monitoring capabilities. When seamlessly installed on various types of railcars, RailBlazer excels in tracking railcar positioning for improved fleet utilization and shunting yard operations, mileage tracking for optimized maintenance scheduling and accurate billing, loading/unloading monitoring, handbrake status for damage prevention, shock detection for safety risk awareness and defect inspections, trip and arrival times monitoring for enhanced service quality.

Association of American Railroads (AAR) estimates that moving rail cars with hand brakes applied results in $US 600M/year in wheel damage. With proven 100% accuracy in reporting handbrake status, RailBlazer ensures a safer and more reliable operational environment and improves maintenance efficiency, thus preventing costly damage down the line. Using GNSS data with advanced algorithms, RailBlazer pinpoints railcar locations with the precision of specific track detection, crucial for optimizing rail yard operations. Additionally, RailBlazer boasts 100% accuracy in confirming loading and over 80% in reporting unloading events within a five-minute window, underscoring its capability to streamline cargo handling. These insights are not just numbers; they translate into actionable improvements on the ground, including reduction in railcar cycle time in shunting yards, higher coordination between loaders, dispatchers, and yard managers, and efficient navigation of push-pull locomotives.

Safety improvements stand out as a key benefit of the RailBlazer system. The ability to detect abnormal shock/impact events with 100% accuracy and alert on railcar health issues provides critical data that helps prevent incidents and enables timely interventions. For instance, a “flat wheel” alert allows for prompt corrective action, highlighting the system’s potential to avert costly and dangerous failures.

On the maintenance front, RailBlazer has facilitated a shift from traditional time-based to more efficient mileage-based maintenance schedules. Based on customers’ reports, this transition has led to a 30% reduction in periodic maintenance procedures and a 28% decrease in overhaul services. Such efficiencies not only lower maintenance costs but also improve railcar availability and reliability. As a result, operators have seen an unprecedently rapid return on their investment within less than six months.

Looking Ahead: The Future of Connected Railcars

The future of rail freight is poised to become more interconnected and efficient, driven by innovations like weight monitoring and RailBlazer’s proprietary Connected Railcar System (CRS), powered by Trilogical’s proprietary Mesh Technology.

This low energy consuming dynamic network connects all the railcars in the trainset and locomotive with no setup hassles forming a virtual network that provides realtime data on railcars positioning in the trainset and allows instant safety alerts on critical failures and End-of-Train events with no cellular coverage dependency.

By incorporating sophisticated features, the industry foresees even greater operational efficiencies and rapid ROI. These innovations position rail freight as a highly competitive and technologically advanced mode of transport, ready to meet the dynamic demands of global logistics.

The integration of cutting-edge telemetry solutions marks a significant breakthrough for the rail freight industry, unlocking unprecedented levels of efficiency and reliability. As railroads and freight operators increasingly adopt these technologies, the potential for enhanced efficiency, safety, and competitiveness in rail freight transportation becomes increasingly tangible. With continuous innovation and refinement, progress is actively underway towards a future where railcars are seamlessly connected, efficient, and dependable digital assets.

More info on RailBlazer could be found here – www.trilogical.com/railblazer